Moulding

Technical Plastic Injection Moulding

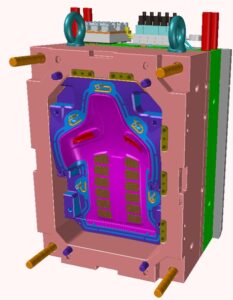

Injection Moulding

The basis of all of the company’s business is it’s Plastic Injection Moulding facilities and capabilities.

The company operates a total of 20 modern injection moulding machines all of which are equipped with handling robots, material loading, drying systems and additional process specific equipment.

In addition to the normal injection moulding process, Certwood can offer:

GAS INJECTION MOULDING

2 SHOT/COLOUR MOULDING

SEQUENTIAL INJECTION HOT RUNNER MOULDING

IN MOULD LABELLING (IML)

INSERT MOULDING

The available machine range consists of the following:

D 50 Tonne 1 off 3 Axis robot

V 85 Tonne 1 off 6 Axis robot

V 130 Tonne 2 off 1 x 6 Axis ; 1 x 3 Axis robot

V 210 Tonne 2 off 3 Axis robots

V 250 Tonne 1 off 3 Axis robot

V 330 Tonne 2 off 3 Axis robots

V 430 Tonne 4 off 3 Axis robots

V 530 Tonne 1 off 3 Axis robots

V 600 Tonne 2 off 3 Axis robots

V 680 Tonne 1 off 3 Axis robot

V 700 Tonne 2 off 1 x 6 Axis ; 1 x 3 Axis robot

V 900 Tonne 1 off 6 Axis robot

Gas Injection

Certwood has 4 machines fitted with Gas Injection technology. We use a Nitrogen generator to supply the gas and this gives far more consistent results than using gas supplied from ‘bottles.’

This equipment, which allows for the injection of Nitrogen gas during the moulding cycle, gives the Company the ability to produce hollow section moulded components. Parts made using this process have good rigidity whilst reducing material weight, cycle times and surface marking.

‘2 Shot’ Moulding

Certwood also has the equipment and technology available to run ‘2 shot’ mouldings in different colours or dissimilar materials.

This process is carried out using Mold Master’s E-Multi second injection unit, which can be mounted directly on to the tool / platen or alternatively on a stand at the side of the tool.

In Mould Labelling

Certwood have 2 machines (700t & 85t) fitted with 6 axis robots that are also equipped to run ‘In Mould Labelling’ (IML) technology.

The robot applies a label to the tool with a static charge using a static generator. The charge is applied almost at the point of location reducing the risk of contamination and maximising the adhesion to the tool surface.

The plastic is then injected and the label is moulded in place.

This eliminates the need for post moulding operations such as applying adhesive labels or printing.

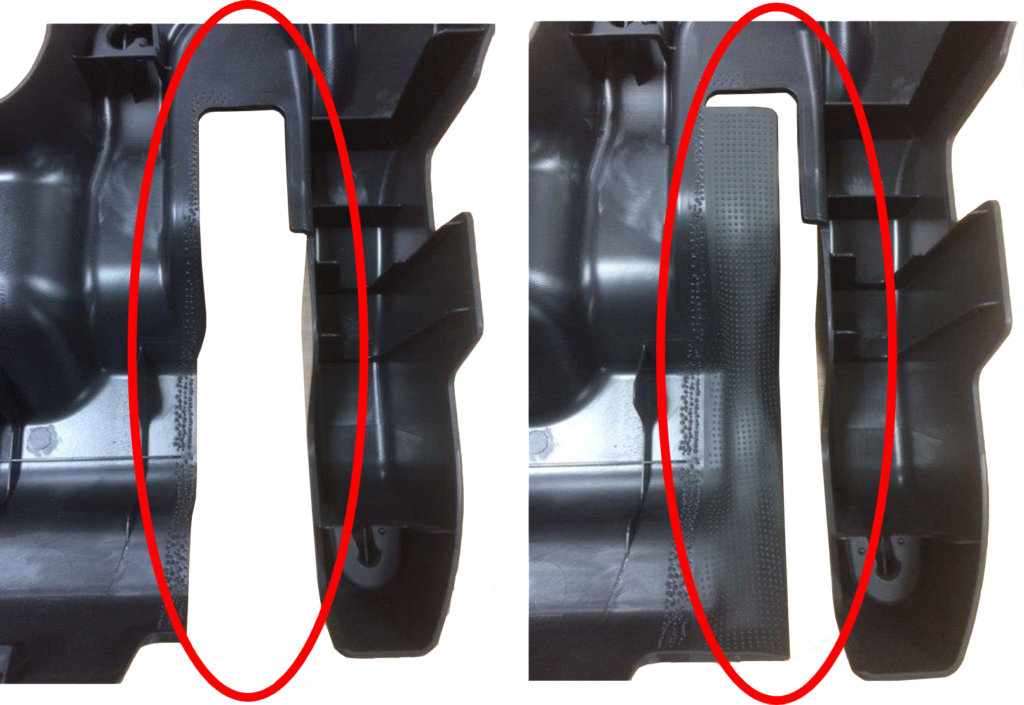

Sequential Hot Runners

Certwood has the capability to run multi-drop, Sequential, Hot Runner tools producing large, complex mouldings with improved filling and reduced surface marking.

Assembly

Certwood is able to offer a range of post moulding activities provided either in house or via sub contract partners including:

General assembly

Ultrasonic welding

Staking

General fabrication